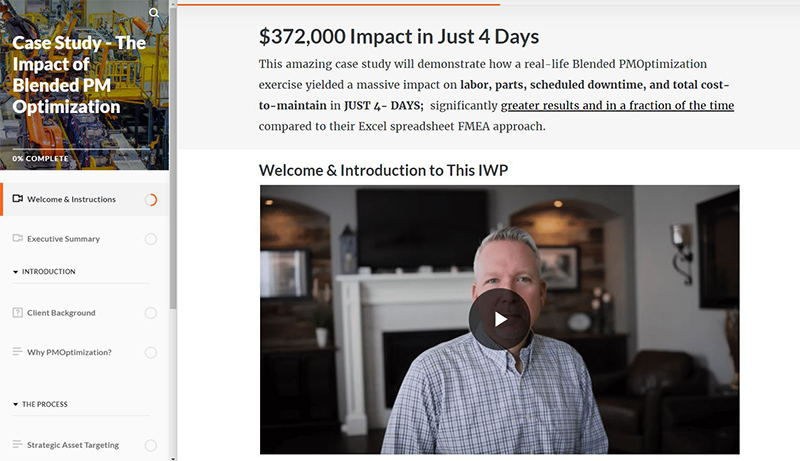

AUTOMATED, SELF-GUIDED, PRACTICAL SYSTEMForget Spreadsheet-Based PM Optimization

After years of facilitating PM Optimization exercises on spreadsheets, we had a major epiphany! We developed a better way; a total solution that solves the most common problems with traditional FMEA and RCM programs in 30% of the time.

Blended PM Optimization goes beyond simply optimizing the preventive maintenance plans into developing an entire strategy for maintaining your assets. Include your digital strategy, develop TPM/ODR Operations reliability, PdM Condition Monitoring, maintenance inspections, lubrication, and replacement activities (where needed).

“Not only were we able to accomplish what would have taken us weeks in a matter of days, the tangible results blew the doors off of our FMEA approach”

~ Global Reliability Manager

Problems We Solve…

- The old process took WAY too long.

- Was dependent on “experts” and intimidating.

- No analytics on the impact of work performed.

- Independent spreadsheets were not scalable.

- Management of the program was manual outside of the exercise.

- Getting the work back into the CMMS was cumbersome & time consuming.

- No way to leverage our CMMS data, work order history or existing job plans.

Solution Details…

The process, management, toolkit and training provides a full end-to-end system that delivers massive results in a practical model. Each aspect of the BPMO System ensures success for the corporate team, local site or individual exercise.

- Analytics-driven PM program baselining

- CoE-Corporate program design

- Strategic asset selection system

- PMO exercise management

- Self-guided PMO process

- Full scale impact analytics

- Exercise leverage library

“This is the fastest, most accurate and practical PM Optimization System available.”

What We Offer…

Blended PM Optimization offers solutions to streamline your processes and meet your challenges.

Following a unique, practical, and automated process…

This self-guided, standardized Blended PM Optimization System will make you an optimization expert in no time. You will revolutionize your overall asset reliability strategy, elevate uptime, and drive down the annual cost-to-maintain in a fraction of the time of traditional methods.

Exercise Effectiveness and Process Efficiency

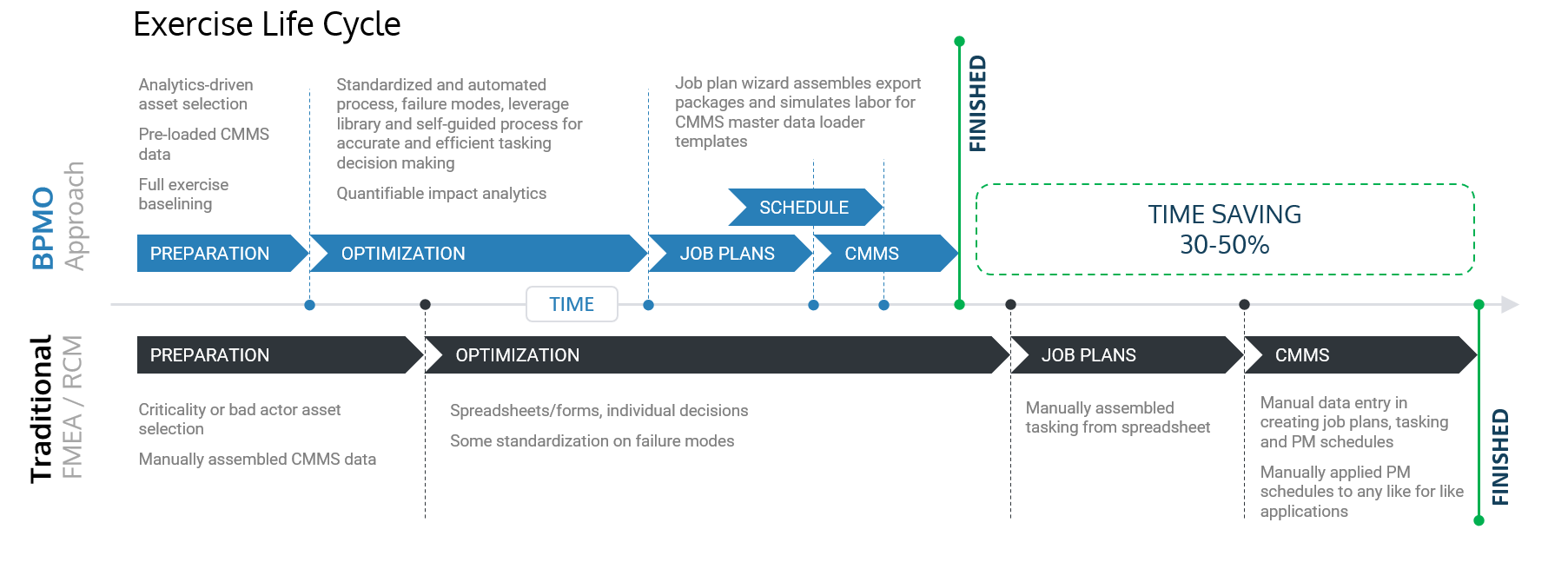

In a side-by-side comparison between traditional FMEA/RCM and our BPMO approach, 30-50% time savings can be achieved using the Asset Analytix Blended PM Optimization approach.

Wondering about these issues?

- How can we convey value to site leadership?

- We want to own the process and not be tied to a consultant

- We don’t have time to do this.

- We already have a PMO program.

There is so much more to this amazing process and technology! Click to request a demo and learn more.